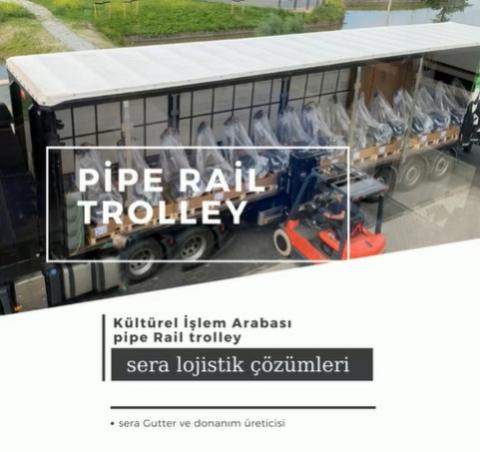

VTS-3000

Pipe Rail trolley is a standard in the 'cultivation under glass' industry. In the pipe rail

system in greenhouses, one is hard put to imagine a greenhouse without a pipe rail trolley. It has now become a standard system in today's modern horticultural industry.

This particular trolley is instantly recognisable by its control cabinet equipped with control buttons and a large red emergency button. All function keys are located on the display.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

The Pipe

Rail Trolley –VTS-3000 is Designed for

Crop Growing in Modern Greenhouses Where Tomatoes are Grown at Considerable

Heights (Max

4.0 M).

Electric

Drive 24V Dc / 70A,

1 Scissors,

Manual

Mechanism for Lifting 2.3M Height,

4 Wheels for

Manually Lifted Maneuver,

Full

Traction Battery (Life Time ~) 1200 Charge Cycles)

Platform:

- Wide Entry at Rear of Car

- Multi at

Work Platform Easy Access

- Safe Entry

And Security Guardrails

- Robust

Operation Keys And Battery Indicator

- Strong And

Unbreakable Speed ​​Governor

- Tool Box

Built In

- Round

Edges That Will Not Damage The Plant Manual Scissors:

- Very Stable Single Scissor Mechanism

- Supported

By 3 Gas Cylinders

- Minimum

Height 540 Mm - Maximum Height 2280 Mm